Highly Engineered Technologic Systems Products: Home

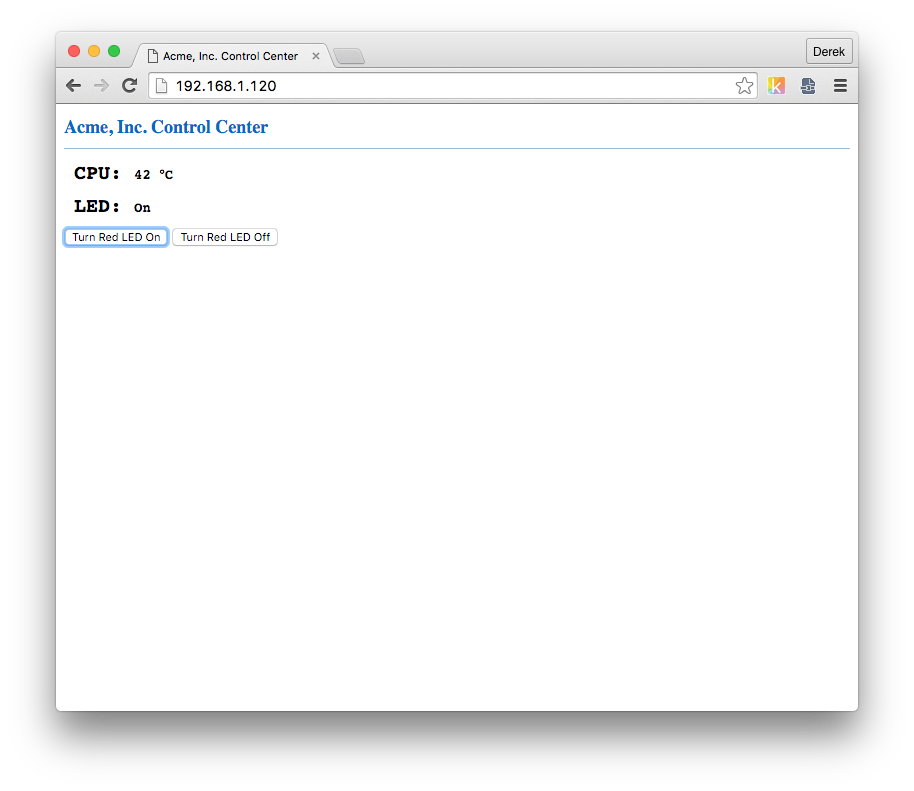

Engineered to withstand the toughest of environments, the TS-7670 or TS-7680 single board computers (SBCs) have no moving parts or fans and can reliably operate in temperatures from -40 °C to 85 °C and high-vibration environments.

The TS-7670 or TS-7680 boot to a preloaded Linux OS from either on-board flash or microSD card, both featuring data reliability insurances. The TS-7670 and TS-7680 use eMMC SLC flash technology for highly reliable data storage, and the microSD cards use our DoubleStore technology for a RAID-like solution.

Furthermore, on the TS-7680 only, an onboard backup power source, called TS-SILO, provides twenty to sixty seconds of reserve power to allow for a graceful shutdown in case of a sudden power outage or brownout.

Because of the inherent challenges with a mobile solution the challenge is collecting and sharing data reliably. This necessitates addressing file system and data corruption, transfer of the data, and operation at extreme temperatures.

File System and Data Integrity.

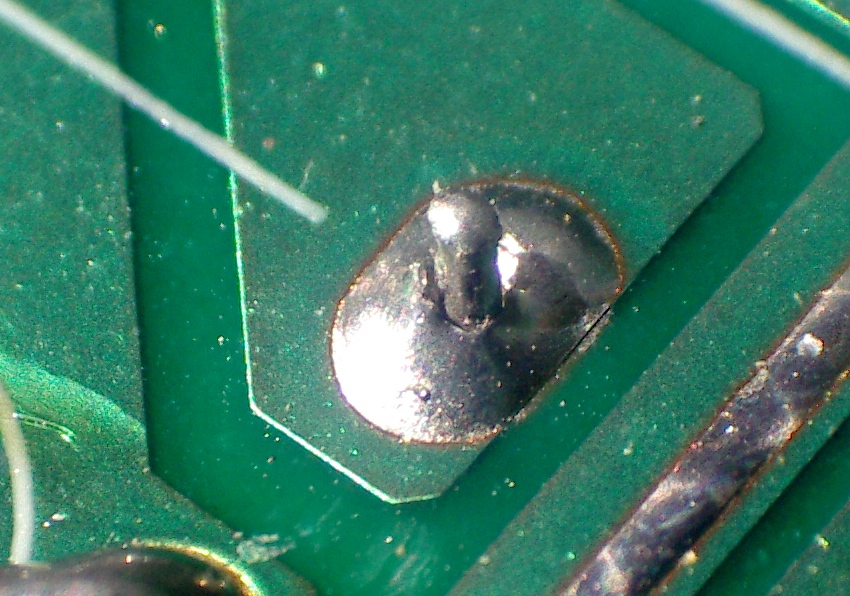

The challenges include additional power supply considerations for a vehicle that is always starting and stopping. When power is unexpectedly cut off from the embedded data logger, there is a high likelihood of filesystem and data corruption.

Data Transfer

Another consideration, is how to transfer the data once you’ve captured it via CAN or GPS. Thankfully, cellular network providers have done a great job at providing an always-available, nationwide service accessible from nearly anywhere. It would make sense to tap into this network using a cellular modem. Then, perhaps when the vehicle returns to a base station, WiFi or Bluetooth connections can be used to share auxiliary, non-real time data.

Operating at Extreme Temperature Ranges

Lastly, you’ll want to consider operating temperature ranges, as the inside a vehicle can easily reach 130 °F to 170 °F (54 °C to 76 °C) and on the opposite, reach “Ice Road Truckers” cold to -50 °F (-45 °C). It’s important to keep these considerations of power, temperature, and connectivity in mind in order to keep all this data safe and sound. The TS-7670 and TS-7680 single board computers are embedded systems which aim to provide reliable, low power, industrial-grade vehicle asset tracking solutions and solve these challenges.

Continue reading “Reliable, Highly Engineered In-Vehicle Data Logging and Tracking TS-7670 and TS-7680”