When washing electronic boards, a common concern among technicians is the purity of their water. Rightfully so because technicians don’t want filthy trace deposits left under and around sensitive components. Some might ask, “If water is bad for electronics, why wash them in the first place?” Washing boards is a common process in the electronics industry because when a board is manufactured or reworked, there is a substance called flux that needs to be removed or it will cause corrosion and longevity issues. Water is a readily available and an effective solution for removing flux. However, technicians need to choose the water carefully. Home

There are several different levels of water purity. Starting with the least pure option, typical tap water can be used for washing boards. The next quality improvement is using carbon filtered water which marginally helps with the contaminants in the tap water. A quality level above that is Deionized water (DI water) which is commonly used in the board washing process at high quality electronics facilities. Using DI water for the board washing process is optimal due to the absence of contaminants in the water. Because DI water is the purest form of water, electronics manufacturers focused on quality use this as a standard for board washing.

Contaminants in tap water, especially “hard” water are known to cause corrosion from salts or minerals left behind, which compromise the longevity of the boards and can even create shorts. DI water is the purest form of water available and is absent of the positive and negative charged ions called anions and cations. To achieve this purity, a company must run their tap water to a tank or series of tanks filled with strong acid cation and strong base anion resin, depending on how they filter the water, to remove the anions and cations.

To increase the effectiveness of the DI water in the washing process many companies use heaters to heat the water up to a specified temperature in which the flux will activate so it can be properly washed off the boards. The heating process is recommended by many flux manufactures during the washing process for the optimal removal of residual flux

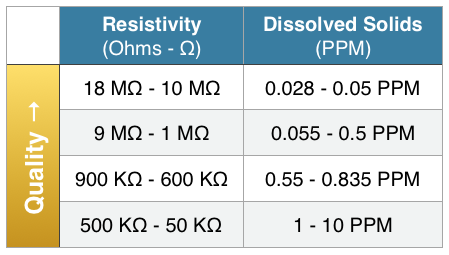

Water purity is measured by the Total Dissolved Solids (TDS) in a volume of water, and ranges from ideal to contaminated as seen in the figure below.

It is important for companies to measure water contamination daily so they know when to replace filters. Measuring water contamination can be easily done by using a TDS metering tool, which measures total PPM, and a resistivity metering tool, which measures electrical resistance. Measuring resistance is necessary because pure water is ideally around 18 MΩ of resistance and that is well under 1 PPM which is the most TDS meters can detect (see chart below). When measuring the DI water for tracking purposes, the typical filter change out time is when the resistivity is at around 50 kΩ or 10 PPM. The ions removed from the tap water eventually clog tank filters which reduce the resistivity of the water and increase the PPM which then causes the water to become less ideal. The process to change out used filters is simple, and companies usually have a contract with the filter supplier to provide an on-site tank exchange.

Here at Technologic systems we have been using the DI water process and are very pleased with the benefits that come with using DI water. We can be certain that all boards will be clean and free of any contaminants after we repair or rework boards. Furthermore, the DI water process is extremely important to our customers because they know we are going the extra mile to ensure all of their products are free from minerals, salts, or other contaminants.

To sum up, tap water is a known bad soluble when cleaning boards in the electronic industry. DI water has many benefits over tap water for the longevity of the boards the customer receives. The pure water washing process will leave boards clean and free of contamination and is far superior to using dirty tap water that might possibly cause defects in the field. Home

Hi Camron, We are very impreased to see your blog. You provide very good information about Deionized Water. Keep it up! premiere sales produce Deionized Water System is produced by removing the dissolved salt in water. Calcium bicarbonate, magnesium sulfate, and sodium chloride are the primary salts present in water and are removed by deionization.

Thanks for all the information.